About

Find Out More About Us

Brief Information About the Enterprise

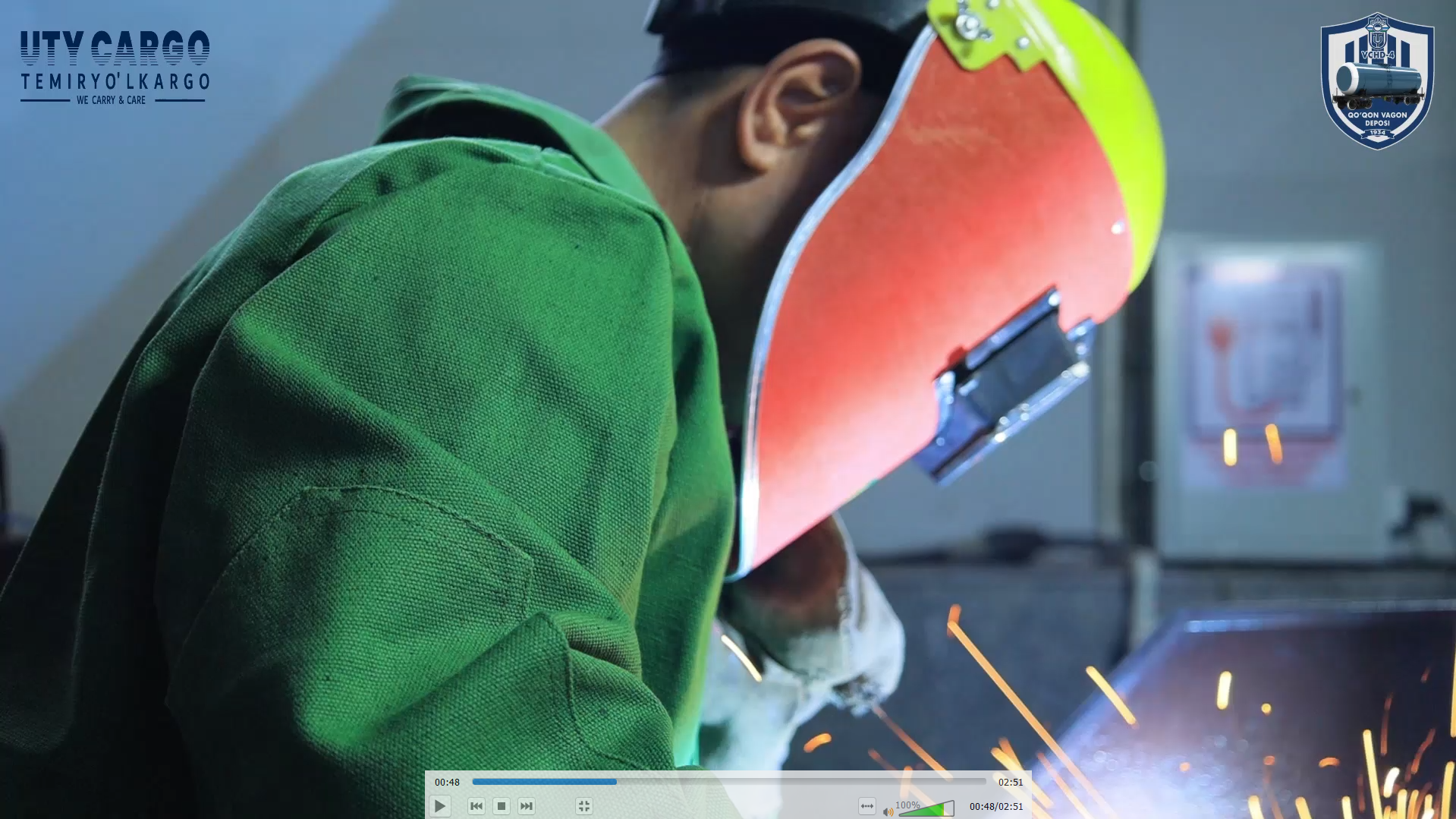

The Kokand Wagon Depot of JSC Temiryolkargo is located at 24 Mehridjan Street, Kokand. The depot was established in 1934 and occupies a land area of 3.75 hectares. Its core activity is the maintenance and repair of freight railcars. Specialists employed at the enterprise: Wagon assembly and repair technicians Welders Turners Milling machine operators Drill operators Electricians Defectoscopists (NDT specialists) Blacksmiths Painters Crane operators Slingers Programmers Engineers

-

Facilities for Scheduled Wagon Repairs

1. Wagon Assembly Shop The shop includes 12 repair stations designed for lifting freight wagons, as well as two overhead cranes with a lifting capacity of 10 tons. It is equipped with 48 lifting supports and four welding stations.

2. Wheel and Roller Shop The shop is divided into sections for dismantling, assembly, wheel tread restoration, and welding. The dismantling section is equipped with four machines for washing wheels, bearings, and wheelset components. The wheel tread restoration section includes three wheel-turning lathes. All sections are equipped with four overhead hoists (2-ton capacity). The yard also contains a 2-ton gantry crane. The shop is additionally equipped with: A heating machine (PPK) for pre-heating wheel surfaces before turning, improving metal machining quality. A vibration diagnostic system for detecting defects in wheelset axleboxes. Magnetic-particle and ultrasonic testing devices, used in accordance with PR NK V2 standards for non-destructive testing of wheelset axles and discs.

3. Bogie and Coupler Repair Shop This shop includes: Washing equipment for bogies and couplers Stands for bogie side frames and bolster beams Turning fixtures and welding stations Inspection areas for non-destructive testing of bogie frames, bolsters, coupler bodies, and draft yokes Test benches for spring group testing A repair and testing bench for triangel assemblies An induction furnace for heating coupler tail parts An overhead hoist with a lifting capacity of 5 tons

4. Automatic Control Section This section is dedicated to the repair of wagon brake systems and mainline pneumatic components. It includes: A washing machine A welding station A grinding machine A conveyor line A monorail hoist Equipment for repairing and testing components of freight wagon brake systems

Clients

Our Clients

Services

Check Our Services

Types of scheduled repairs

Repair of carriage parts

Services for unloading and loading, weighing of wagons

Wagon cutting services

Additional services

Preparation of various specialized technical equipment, stands and simulators

Portfolio

Check Our Portfolio

News

Latest News & Updates

Team

Our Hardworking Team

Boyqo'ziyev A.V.

Factory manager

Yo'ldashev M.O.

Chief engineer

Jamoldinov B.Sh.

Deputy chiefContact

Need Help? Contact Us

Address

Kokand, Mehrjon ko'cha 24, Uzbekistan

Call Us

+998 90 123 45 67

Email Us

vchd4.texnolog@gmail.com